9812-A Cochiti Rd SE

Albuquerque, NM 87123

(505) 292-5532 or (800) 3265632

Metal Finishing

We offer a variety of metal finishing, Cerakote, Bluing and Parkerizing. We also have a wide variety of abrasive media giving us the ability to create almost any texture on the surface of your firearm.

"Click Here to View Photo Gallery"

Score High Gunsmithing is a Certified Cerakote Applicator

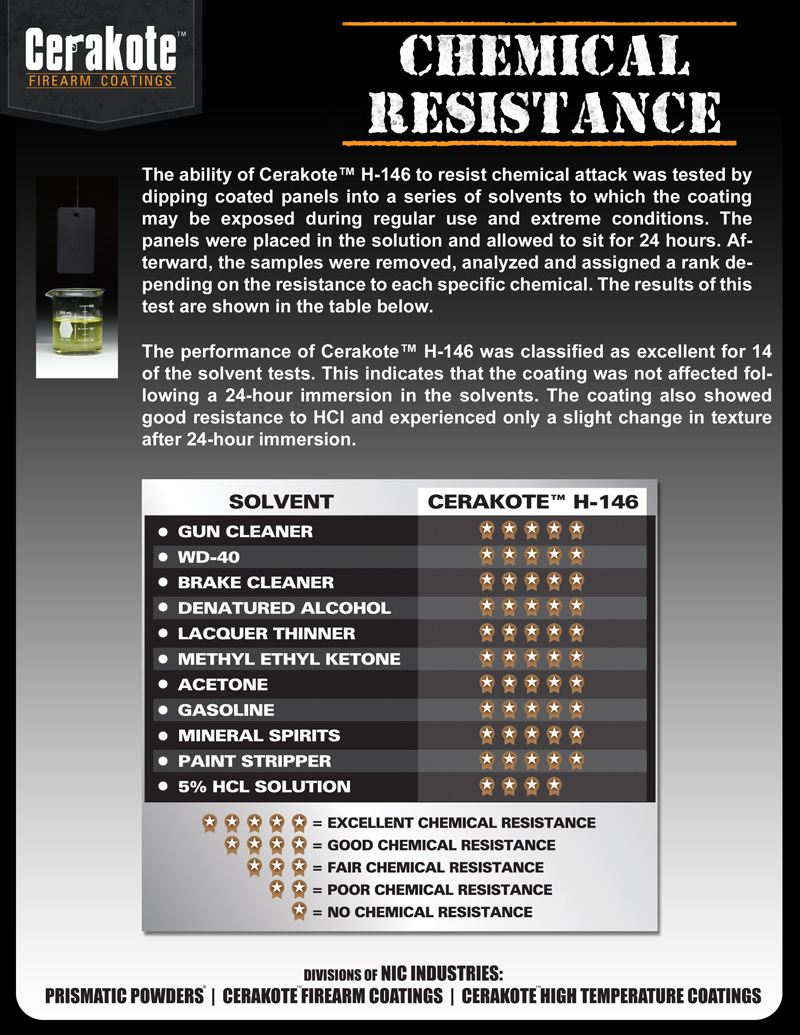

H-Series Cerakote in our opinion is the toughest coating available and comes in a wide variety of colors. It can be applied to all metals, polymers, fiberglass and even optics. For the utmost in strength and toughness, H-Series Cerakote is cured at high temperatures, however for items such as fiberglass and optics it can be cured at a lower temperature for a longer period of time and still retain much of its high temperature cured properties. Also available is C-Series Cerakote. Obtainable in many colors it is a room temperature cure (RTC) coating and once cured has the ability to withstand temperatures as high as 1700 Deg. F without discoloring.

You can follow one of two paths to procure a Cerakote finish on your firearm. The least expensive is to do all of your own disassembly and reassembly and deliver to us only the parts that you would like to have coated. This method incurs all the pricing in Table 1 minus $25.00. The second method is to send us your complete firearm and we will disassemble and reassemble it. The charges in Table 2, break down firearms into three categories and includes disassembly and reassembly. Scope mounting may incur additional charges. Our staff is composed of professional gunsmiths, if we find any anomalies or repairs necessary, we will contact you and go over the needed repairs and their cost before any work is done. You will be able to calculate the price of your desired Cerakote finish by adding the Cerakote charges in Table 1 to the appropriate charges in Table 2.

Table 3 is for special situations and/or additional charges and assumes that all disassembly has been done prior to the firearm arriving at the shop.

Click here to visit the Crerakote web site to shop colors and to request color sample.

Glossary of Terms

Layering.

Appling a layered pattern is achieved by coating an entire part with one

base color then partially oven curing that part for a set time allowing the part

to be handled without damaging the finish. This step of applying color on top

of color is repeated for each additional color to achieve a desired multicolor

pattern.

Stenciled pattern using layering.

This is a layering pattern that uses high temperature adhesive stencils

to achieve a desired pattern. This pattern will have very sharp and defined

edges of each of the colors of the various layers.

Layering without stencils.

This pattern is done free hand and has softer less defined color

transitions that will often fade away transitioning to the underlying color

layer.

Additional color applied to certain parts (no

layering)

An example of this would be a pistol frame of one color and all of the

attached parts being a different color.

"Click Here to View Photo Gallery"

"Click Here to View Photo Gallery"

Parkerizing $150.00

Is a dark gray corrosion resistant mil spec finish also known as a Zinc

Phosphate finish. It can only be applied to Carbon steel parts.

Stainless steel, aluminum or brass cannot be parkerized

$165.00 for most firearms

Our bluing process is what is known as hot bluing. We have our own bluing salt formula that yields a very dark almost black finish on brightly polished steel. We can create different effect depending on the metal preparation.

Q&A

Q. How durable is bluing?

A. Bluing is not a coating on top of the metal, it is the metal its self. The surface has been oxidized and there for it reflects a different light. Because bluing is not a coating it offers very little protection against rust and corrosion. Wear resistance will vary depending on the hardness of the metal. Bluing will ware off of soft steel quite easily ware as it is a bit more robust on harder steels.